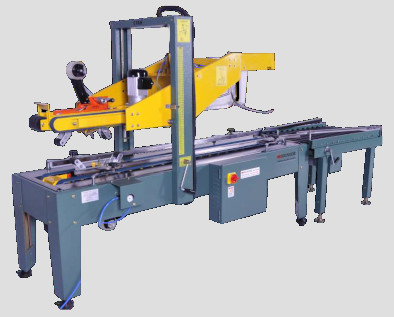

Packaging Automation – Carton Sealing/Tapping Machine

TSW – Authorized Partner of Signode India

At TSW Packaging Solutions, we are proud to be an authorized partner of Signode India, a globally recognized leader in industrial packaging solutions. Our carton sealing/tapping machines, manufactured by Signode India, are designed to enhance your packaging efficiency with cutting-edge automation, precision, and durability.

As a trusted tapping machine supplier in Pune, PCMC, Nashik, and across Maharashtra, we bring you reliable, high-performance solutions that cater to diverse industries, ensuring seamless and cost-effective packaging operations.

Why Choose Signode Tapping Machines from TSW?

- Industry-Leading Technology – Manufactured by Signode India, ensuring superior quality and reliability.

- Authorized Partnership Advantage – Get genuine Signode machines with expert support and after-sales service.

- High-Speed & Precision Sealing – Automates the carton sealing process for faster throughput.

- Consistent & Secure Packaging – Ensures uniform tape application, reducing transit damage and packaging inconsistencies.

- Cost-Effective & Labor-Saving – Optimizes material usage and reduces manual labor costs.

Types of Tapping Machines We Offer

1. Batch Type Tapping Machine

- Designed for consistent carton sizes and batch processing.

- Ensures precise, uniform sealing for standardized packaging.

- Best for industries with stable product packaging requirements.

4AM

FTM

5FAM

2. Random Type Tapping Machine

- Adaptable to cartons of varying sizes and dimensions.

- Handles mixed packaging lines efficiently.

- Ideal for dynamic production environments with diverse packaging needs.

4RM

6RM

5FRM

Why Buy from an Authorized Signode Partner?

- 100% Genuine Signode Machines with manufacturer-backed warranty.

- Expert Consultation & Custom Solutions for your packaging needs.

- On-Site Installation & Training by professionals.

- Dedicated After-Sales Support & Maintenance Services.

Get Your Signode Tapping Machine Today!

As an authorized partner of Signode India, TSW Packaging Solutions ensures you get the best-in-class packaging automation for your business. Contact us today for a customized packaging solution that meets your requirements.