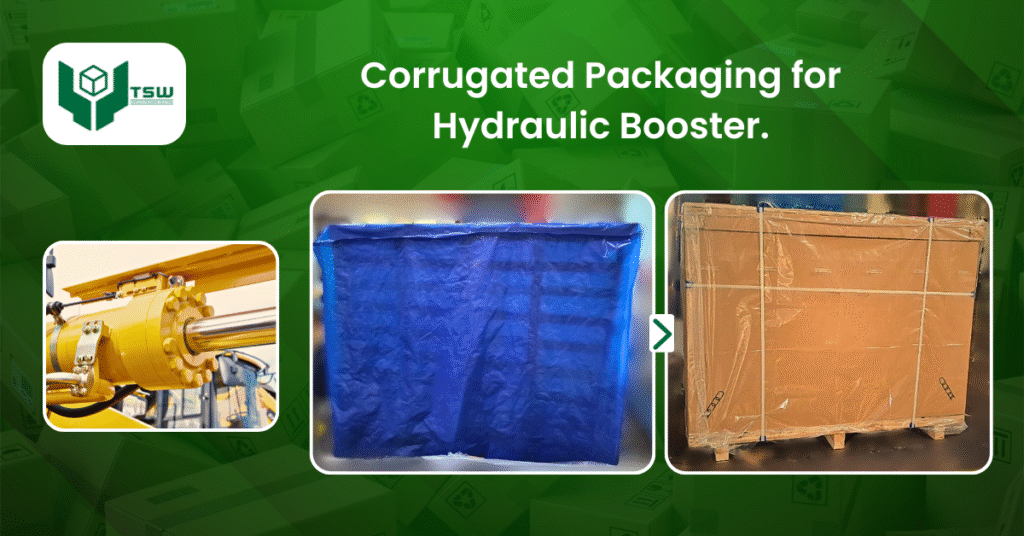

Overview:

Our customer, a leading manufacturer of industrial equipment, sought a more efficient and sustainable packaging solution for their Hydraulic Booster, which weighs 1.5 tons. Previously, they used wooden packaging, which posed several challenges, including safety risks, high weight, and limited branding opportunities.

Challenges:

The customers faced multiple issues with wooden packaging, including:

- Heavy weight, making transportation and handling difficult.

- Worker safety concerns due to the use of nails and splinters.

- Limited branding options, reducing the visibility of their brand.

- Environmental concerns, as wooden packaging is less sustainable.

- High labor costs associated with assembling wooden crates.

- Difficult customization, limiting packaging adaptability.

Solution:

We introduced a Heavy Duty corrugated packaging solution specifically designed to handle the 1.5-ton Hydraulic Booster while addressing all previous challenges. Our customized corrugated solution was engineered with reinforced layers and advanced structural integrity to ensure maximum protection during storage and transit.

Key Benefits:

- Improved Branding – The corrugated packaging allowed for high-quality printing, enhancing brand visibility and presentation.

- Enhanced Worker Safety – Eliminating nails and splinters reduced the risk of injuries, ensuring a safer work environment.

- Eco-Friendly Solution – The switch to corrugated material aligned with sustainability goals, reducing environmental impact.

- Lightweight & Cost-Effective – Significantly lighter than wooden packaging, reducing shipping costs and improving handling efficiency.

- More Customization Options – The new design allowed for tailored packaging sizes and additional protective features.

- Ease of Packing – Simplified the packing process, reducing labor time and increasing operational efficiency.

- Customer Satisfaction – The improved packaging solution not only met our client’s needs but also enhanced the experience of their final customers by ensuring product safety and easier handling.

Outcome:

After implementing the corrugated packaging solution, the client experienced:

- A 30% reduction in packaging weight.

- A 20% cost savings on packaging and transportation.

- A 50% improvement in packaging and handling efficiency.

- A higher level of satisfaction among workers and final customers.

Conclusion:

The transition from wooden to corrugated packaging proved to be a game-changer for our customer. It not only improved branding, safety, and sustainability but also streamlined logistics, ultimately enhancing the overall packaging experience. Our customized corrugated packaging solution successfully addressed all key challenges, ensuring long-term benefits for the client and their customers.